In this kind of transaction, the second company is referred to as the OEM, or original equipment manufacturer. Read More…

Since 1920, Hankscraft Inc. has been a leader in the contract manufacturing industry, producing dependable and high-quality products for all of our customers. We pride ourselves on our contributions to the industry and being industry experts. From plastics, to metals, to assembly we can manage your entire program.

Bihler of America Inc. is a contract manufacturer and packager. Bihler serves the electrical, medical, automotive, appliance, electronic, and military industries among others. Bihler can stamp, form, weld, tap, insert screws, and construct components and assemblies for a variety of products. Bihler satisfies customers through cost-effective and quality manufacturing services.

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

Kalow is a leading manufacturer of industrial balers, garbage balers, scrap metal balers, baling presses, trash compactors and recycling equipment. Kalow provides quality industrial balers and products for a variety of industries and markets. Contact us for your industrial baler needs today!

BRI, an ISO 9001:2008 manufacturer, was founded in Winchester, VA in 1985 as a custom injection molder and assembler of plastic parts. We offer: custom injection molding, contract manufacturing, sonic welding, pad printing/hot stamping, plastic painting and hydrografix decoration. We have extensive success in providing customers with tooling and procurement, molding, assembly and retail packaging.

If you have a custom manufacturing challenge, ALKAB Contract Manufacturing, Inc. can help. We are a machining and fabricating job shop that produces custom machinery, equipment, tooling and individual component parts. Our capabilities include large/heavy part machining, small part machining, welding and fabricating, and electromechanical assembly. We can process prototypes, one-offs, and small...

More Contract Manufacturing Companies

Contract manufacturers are often used when an original equipment manufacturer (OEM) needs assistance with their manufacturing process. This is a practice often called outsource manufacturing. Outsourcing can be beneficial for both companies involved. The outsourced firm can be a company in the same country as the OEM, but often times it is a foreign company. Sometimes the OEM is not a manufacturing company or does not physically make the product being outsourced.

By purchasing the product from contract manufacturers, the OEM saves money on engineering, infrastructure and assembly costs. In recent years, the global economy has seen more and more OEMs looking to foreign contract manufacturers to manufacture their products. Although many people think of outsourcing as the process of buying products from a company outside of the country, contract manufacturing actually includes any transaction where an OEM has its product manufactured by another company.

Companies in the aerospace, computer, telecommunication, energy, automotive, medical, military and electronic industries utilize contract manufacturing to produce devices that are needed on a daily basis. A few types of contract manufacturing are CNC machining, precision machining, complex assembly, grinding and aluminum die casting.

Contract manufacturing is many benefits. The amount of money saved is tremendous because the hiring company does not need to pay for a facility or the equipment. They also are not in charge of training, managing and paying a labor force. Many companies look to less developed countries for their inexpensive labor costs.

Another benefit is the contract, often lasting between three and five years. This guarantees steady work and revenue for the hired company. Contract manufacturers have many specialized skills that the hiring company does not possess and are likely to already have business relationships with suppliers, production efficiencies that include quality control and quality assurance processes. The final benefit of contract manufacturing is the ability of both companies to focus on their core competencies.

Contract manufacturing has its disadvantages as well. As soon as the OEM signs the contract it loses control over the manufacturing and quality of the product. This is why it is important to have a good relationship with the other company in the contract. Another disadvantage is the potential of losing your intellectual property because you are allowing others to see your formulas and technologies. Another risk of outsourcing, especially to foreign manufacturers, is the difference of time, language and cultures as well as long lead times.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

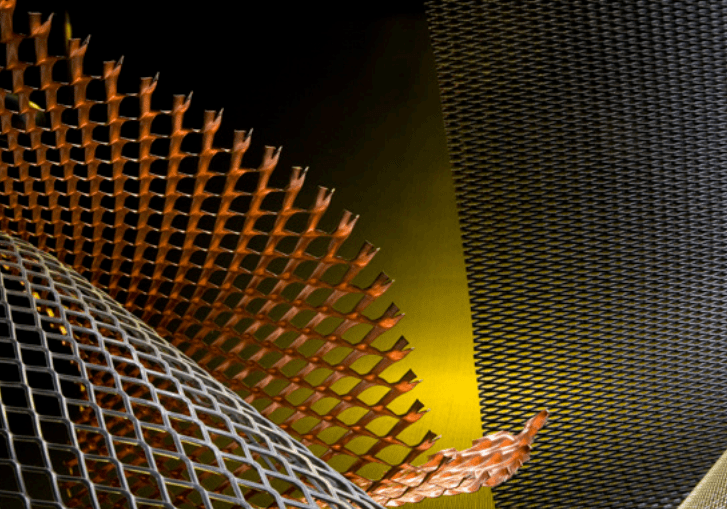

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

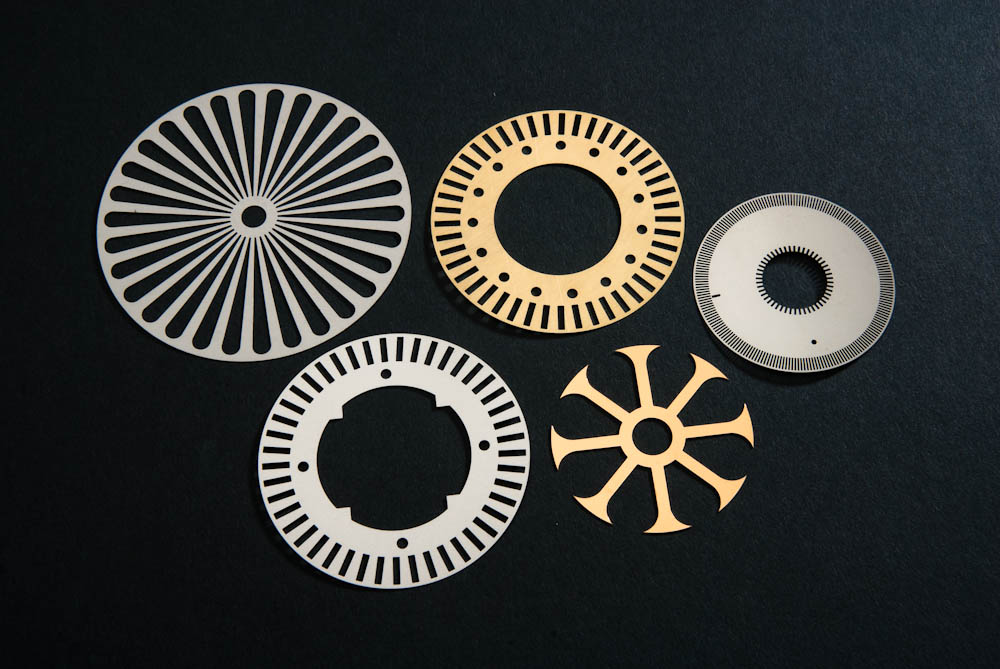

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

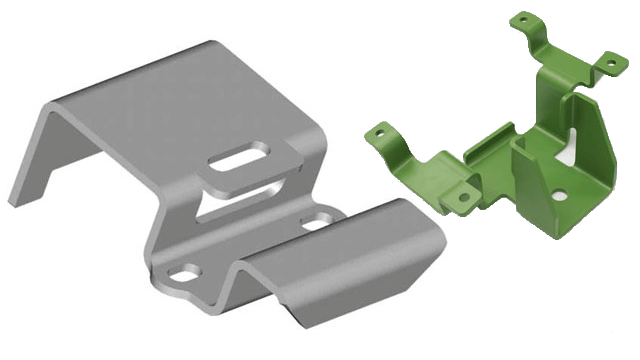

Metal Fabrication Metal Stampings

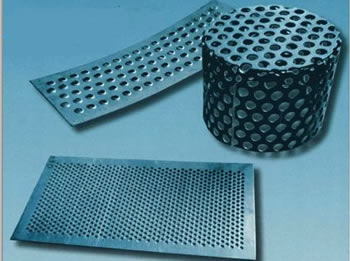

Metal Stampings Perforated Metals

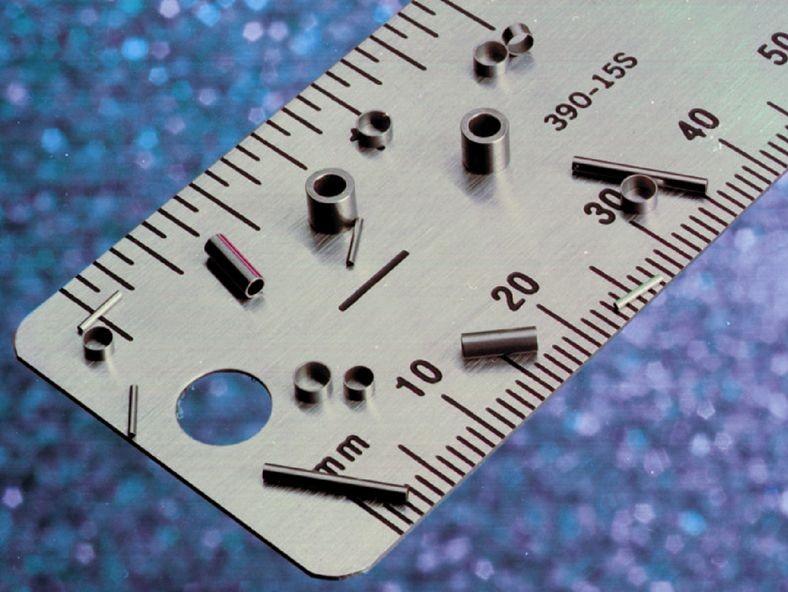

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services