The term “contract manufacturing” refers to the manufacturing services that some manufacturers perform on a contractual basis for other businesses. The companies for which they perform contract manufacturing services are called “original equipment manufacturers,” or OEMs. Contract manufacturing is also known as private label manufacturing or outsource manufacturing. Read More…

More Contract Manufacturing Companies

Even though the word “outsourcing” usually refers to manufacturing outside of North America, it can also refer to any manufacturing that is done outside of the OEM.

Applications

Many businesses rely on contract manufacturing because it represents a cost savings, and it allows them to maximize their resources and pay for the upkeep of expensive equipment.

Among the various contract manufacturing services that contract manufacturers provide are contract machining, contract assembly, and subcontracting.

Contract manufacturers have a wide variety of capabilities. Among the specific manufacturing processes contractors use are milling, sawing, planning, tapping, drilling, turning, boring, and grinding. New technologies with growing demand among contract manufacturers include electrical discharge, ultrasonic and electrochemical machining, and more.

Major companies use various types of contract manufacturing services for these jobs. Some of those industries from which these companies come include marine, automotive, aerospace, food and beverage, chemical, pharmaceuticals, military and defense, medicine and healthcare, and electronics.

History

Modern contract manufacturing is a fairly new service. It kicked off during the mid-Space Age, in the 1970s. During those years, NASA, which had been going strong for a long time, started to receive less and less funding for their projects. Seeing that he was losing money, an Alabama based governmental subcontractor named Olin King began contracting out his services to engineering and technology companies such as IBM. Other companies, like Solectron, quickly followed suit. They offered to build entire electronic products, as well as components of products. In 1981, IBM issued their first computers built by a contract manufacturer.

Throughout the 1980s, companies in the electronics industry used contract manufacturers for more and more applications, because they found that some in-plant manufacturing processes could cause environmental issues. By outsourcing their engineering and assembly processes, they were able to avoid these issues completely.

In the early ‘90s, contract manufacturers started diversifying their services and reached out to other markets, such as pharmaceuticals, clothing and textiles, and toy production. Their service capabilities were heavily expanded by CNC machining, a technology that had been slowly developing for a few decades, in a number of ways. CNC machining, for example, offered companies capabilities like faster lead time, higher production volumes, better quality parts and products, higher tolerances, and more intricacy of design.

Today, contract manufacturing services are extremely lucrative. Improvements in communication and transportation have made contract manufacturing an efficient and popular means of production. People have been hiring specialized trade workers to make products for them for centuries, but technology now allows for this to happen on a global scale. Parts can be designed by a company in England, assembled by a company in China using materials from Brazil and then sold to a company in the United States. As time goes on, we expect this trend to continue. Data shows that the contract manufacturing industry is growing at an annual rate of 10%. Also, the global contract electronics manufacturing market is growing at a rate of around 15% a year, while pharmaceutical contract manufacturing is growing by about 7.5% a year.

Service Details

This is how contract manufacturing works, from start to finish.

- Often, the company looking for a contractor starts by advertising its project and requesting bids. This is especially common in the government.

- After looking through the bids, an original equipment manufacturer (OEM) picks a few manufacturers to which to discuss their application.

- Based on their discussions, the OEM then decides which manufacturing company they want, and agrees to work with them.

- Under normal circumstances, the OEM and contract manufacturing company establish a contractual agreement. This agreement specifies a particular job that the contract manufacturer must complete, and the timeframe and budget upon which they have both agreed. They may define this timeframe as hours, days, weeks, months, or years. Manufacturing contracts generally last between 3 and 5 years, although they can vary greatly depending on the nature of the project.

Sometimes, they eliminate the timeframe altogether, and replace it with a measurable output goal. Having this contract in writing is beneficial to both parties, as it establishes accountability. Also, if an OEM is working with a foreign manufacturer, these written agreements help assuage language barriers.

- Once hired, the contract manufacturer produces goods or performs services for the OEM on a regular basis. They usually apply the OEM company logo to any goods before they ship them.

Contract Considerations

Contract manufacturers play a vital role in designing goods and planning services for their potential customers. When engaging in contract manufacturing, these companies work closely with their clients to understand their specific requirements, expectations, and desired outcomes. The process typically begins with a thorough analysis of the client’s needs, including product specifications, quality standards, and regulatory requirements. Based on this information, the contract manufacturer’s design team collaborates with the client to develop a tailored solution that meets their unique needs. This involves conceptualizing, prototyping, and refining the product or service design until it aligns with the client’s vision. The contract manufacturer also considers factors such as cost-efficiency, scalability, and manufacturability during the design phase. Once the design is finalized, the contract manufacturer plans the production process, including sourcing materials, allocating resources, and establishing timelines. They ensure that all necessary steps are taken to deliver the desired goods or services efficiently and effectively, meeting the agreed-upon quality standards and delivery schedules. Through this collaborative approach, contract manufacturers strive to provide their potential customers with customized, high-quality products and services that align with their unique needs and market demands.

Machinery Used

Contract manufacturers utilize a diverse range of equipment and tools depending on the specific requirements of their clients and the industry they operate in. Manufacturing and assembly equipment play a crucial role, which can include CNC machines, injection molding machines, robotic systems, and testing equipment. For metalworking and fabrication, tools like lathes, milling machines, and welding machines are utilized. In the electronics industry, on the other hand, surface mount technology (SMT) machines, testing equipment, and pick-and-place machines are essential. Packaging and labeling machinery, such as blister packaging machines and labeling machines, are additionally used for the final presentation of products. Quality assurance and testing equipment, including coordinate measuring machines and environmental testing chambers, ensure that products meet the required standards. In industries like pharmaceuticals and semiconductor manufacturing, meanwhile, cleanroom facilities equipped with specialized HVAC systems and air filtration units are utilized to maintain a controlled environment. The specific equipment employed by contract manufacturers depends on the industry, product complexity, and client specifications, enabling them to deliver high-quality and customized manufacturing services.

Variations and Similar Services

Examples of contract manufacturing variations include contract machining, contract assembly, contract packaging, nearshoring, outsource manufacturing, industrial contract manufacturing, military contract manufacturing, electronic contract manufacturing, PCB assembly, aerospace contract manufacturing, pharmaceutical contract manufacturing, medical device contract manufacturing, chemical contract manufacturing, and contract sewing.

Contract machining is a service usually performed at a contract manufacturing company’s machine shop. There, they machine a variety of materials, so that they are ready to move onto the next step of design and manufacturing.

Contract assembly services involve the assembly of parts and products. Contract assembly services take place on machines like assembly lines. Contract assemblers may assemble components using man power, or they may assemble components using automatic machinery.

Contract packaging is the service of carrying out packaging operators on a contractual basis. Contract manufacturers that perform packaging can be called contract packagers or co-packers. They usually manufacture items and packaging materials like blister packaging, clam shell packaging, shrink wrap, and labeling.

Nearshoring is the name given to contract manufacturing that is performed in the same country as the hiring company or a bordering country. The benefit of nearshoring is that it cuts down on shipping costs and project lead times.

Outsource manufacturing, though it technically means the same thing as contract manufacturing, also refers to those contract manufacturing services that OEMs commission from international sources.

Industrial contract manufacturing is the subtype of contract manufacturing that focuses on the production of industrial equipment and the performance of industrial processes. Examples include commuter rail lines, rubber products, textiles, heavy machinery, and plastic injection molding. Industrial contract manufacturers can also produce some industrial electronic items.

Military contract manufacturing, sometimes called defense contracting, is a type of contract manufacturing completed exclusively by government approved companies. These companies produce items for the military such as weapons, body armor, aircrafts, and shelters. To supplement their income when not working for the government, military contract manufacturers also take on large numbers of non-governmental companies.

Electronic contract manufacturing is one of the largest contract manufacturing fields. Electronic contract manufacturers produce all sorts of electronic products and parts, including anything from cell phones to semiconductors.

PCB assembly, or printed circuit board assembly, is a subcategory of electronic contract manufacturing. PCB assembly services are just as they sound. PCBs can be used to support a wide range of electronic products.

Aerospace contract manufacturing is a contract manufacturing field that produces parts and products such as helicopters, jets, airplanes, and unmanned aircrafts. Depending on their customer, they also have to make products to very strict standards.

Pharmaceutical contract manufacturing is usually carried out by pharma contract companies called contract development and manufacturing companies (CDMCs) or contract manufacturing organizations (CMO). They make products for pharmaceutical companies, like liquid medicine, capsules, pills, creams, and lotions. They also make all packaging of these products.

Medical device contract manufacturing companies make medical devices and medical tools for other companies to sell.

Chemical contract manufacturing is a branch of contract manufacturer that focuses on manufacturing equipment and synthesizing chemicals and materials for the use another company or organization. These chemicals and materials are usually the starting pieces that customers need to carry out their applications.

Contract sewing is a branch of contract manufacturing that provides for OEMS not only items like clothes, but also items like carrying cases, table umbrellas, tents, cushions and upholstery, blankets, anti-static computer cloths, and more. Contract sewers provide services like label stitching and use a wide variety of materials, from velvet to vinyl.

Benefits

Both parties involved in a contract manufacturing arrangement experience many benefits. Using contract manufacturing offers several benefits to companies seeking to outsource their production processes. Firstly, it allows businesses to focus on their core competencies and strategic activities while entrusting the manufacturing aspects to specialized contract manufacturers. This frees up internal resources, reduces operational complexities, and enables companies to allocate more time and effort to areas such as product development, marketing, and sales. Secondly, contract manufacturing provides access to specialized expertise and technologies that may not be available in-house. Contract manufacturers often possess extensive industry knowledge, experience, and state-of-the-art equipment, which can lead to improved product quality, efficiency, and innovation. Thirdly, contract manufacturing offers flexibility and scalability, allowing companies to adapt production volumes based on market demand. This eliminates the need for significant upfront investments in manufacturing facilities and equipment, making it a cost-effective option. Additionally, contract manufacturing enables companies to enter new markets or launch new products more quickly, leveraging the expertise and existing infrastructure of the contract manufacturer. Lastly, contract manufacturing can provide geographical advantages, such as proximity to target markets or access to lower-cost labor and raw materials in specific regions, enhancing competitiveness and cost-efficiency. Overall, contract manufacturing offers companies numerous advantages, including increased focus, access to expertise and technology, flexibility, speed to market, and cost optimization.

The party performing the work, which is the contract manufacturer, also derives several benefits from engaging in contract manufacturing arrangements. Firstly, contract manufacturing provides a steady stream of work and revenue for the manufacturer. By serving multiple clients and taking on production projects on a contract basis, the manufacturer can maintain a consistent workload and utilize their production capacity effectively. This can help them optimize their resources and achieve economies of scale, resulting in increased efficiency and profitability. Secondly, contract manufacturing allows manufacturers to expand their expertise and capabilities by working across different industries and product categories. This exposure to diverse projects fosters knowledge and skill development, enabling the contract manufacturer to enhance their competencies and stay competitive in the market. Thirdly, contract manufacturing can lead to long-term partnerships and recurring business. If the manufacturer consistently delivers high-quality products and services, they can build a reputation for reliability and become a preferred choice for clients seeking manufacturing solutions. This can contribute to stable, ongoing contracts and a loyal customer base. Lastly, contract manufacturing offers opportunities for collaboration and innovation. Working with various clients exposes the manufacturer to different perspectives and ideas, fostering creativity and driving continuous improvement in their manufacturing processes. In summary, contract manufacturers benefit from a consistent workload, skill development, long-term partnerships, and opportunities for collaboration and innovation.

Things to Consider

Before signing an agreement with a contract manufacturer, you need to carefully consider a number of things. These include if a manufacturer has access to the best technology, their capabilities, if they can meet your standard requirements, their delivery options and how long products will take to arrive, if they offer payment plans, their reputation, and their years in business. If a manufacturer cannot produce and ship parts in the specified timeframe, look for another contract manufacturer who can.

In addition, any manufacturer with which you work should be willing to work for you on a trial basis before you sign a contract. An unwillingness to do so is a red flag, as it indicates a lack of transparency. If they are unwilling to work out payment plans, discuss customizations or provide quality assurances, watch out; these are also red flags.

Most contract manufacturers want to show their customers that they are trustworthy and a good choice for a long-time partner. They are also happy to demonstrate that they are organized and have the capabilities to track all their customer orders. If you don’t get the impression of such attitudes and capabilities with a potential contract manufacturer, steer clear. Untrustworthy contract manufacturers could cause big problems. For one, they could present you with goods or services of subpar quality. In addition, if you are sharing your technology and specifications for production, a dishonest manufacturer could force you to participate in intellectual property disputes.

Global communication makes it easy for companies to advertise and bid on manufacturing contracts and even take orders that help manage production. Nevertheless, finding a quality pool of contract manufacturers can be a daunting task. To help you in that endeavor, we have put together a list of those contract manufacturers we have found to be reliable producers of high quality work. You will find their information wedged between these paragraphs. For the best results, we recommend you look them over, note their capabilities and offers, and narrow them down to three or four candidates. After that, reach out to each of them to talk over your application. After you have spoken with each potential supplier, figure out which one is right for you, and call them back to negotiate a contract.

Aerospace Contract Manufacturing

Chemical Contract Manufacturing

Contract Manufacturers

Electronic Contract Manufacturing

Medical Device Contract Manufacturing

Military Contract Manufacturing

Outsource Manufacturing

Pharmaceutical Contract Manufacturing

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

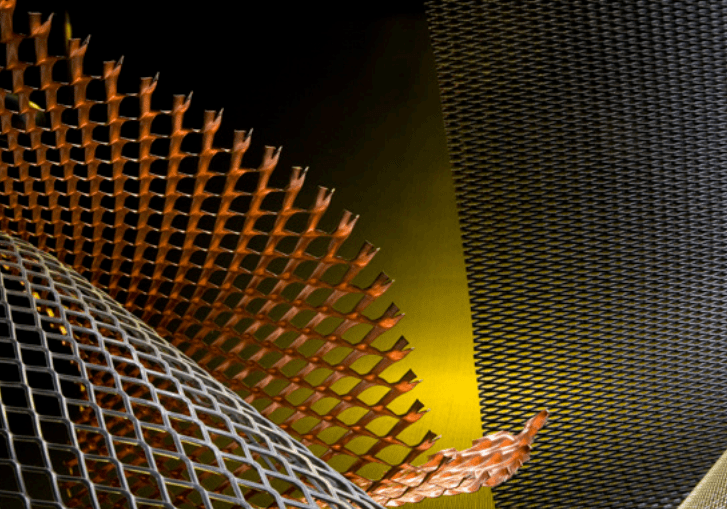

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

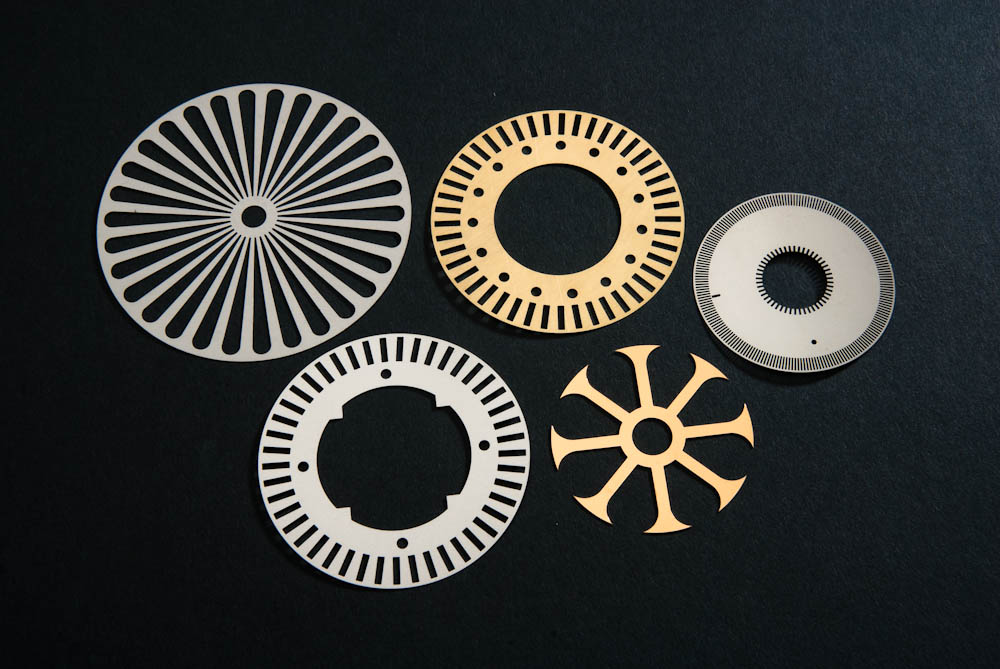

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

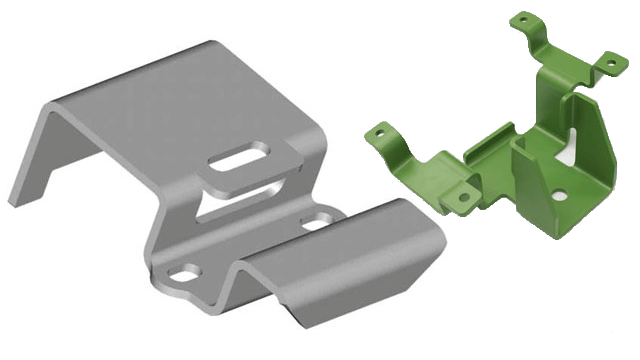

Metal Fabrication Metal Stampings

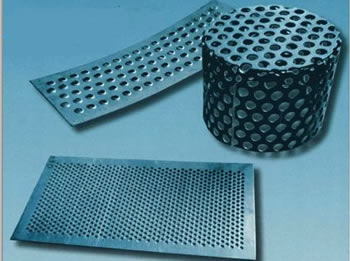

Metal Stampings Perforated Metals

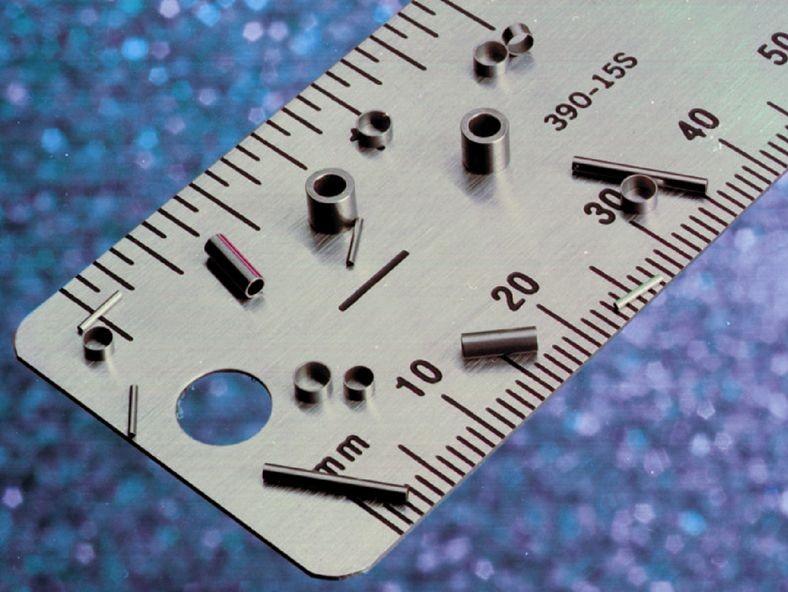

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

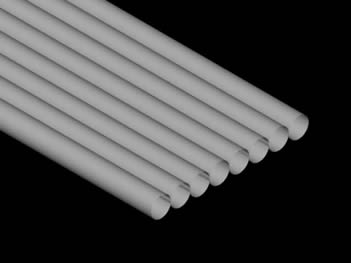

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services