Metal Cutting Services Manufacturing Companies

Broaching

CNC Machining

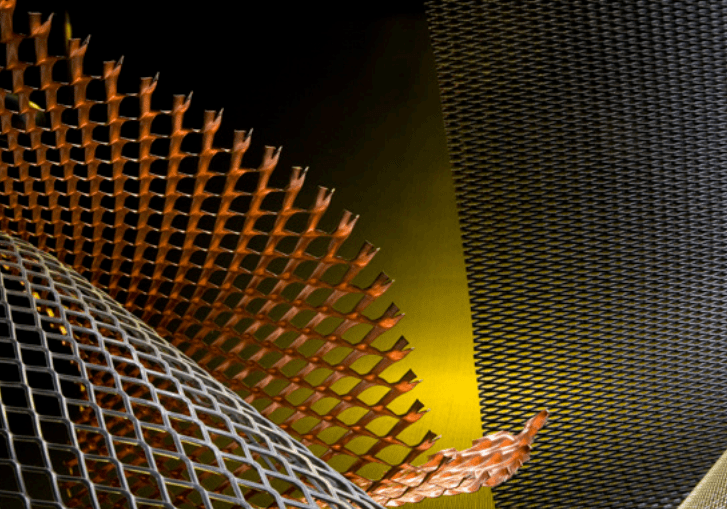

Expanded Metals

Laser Cutting

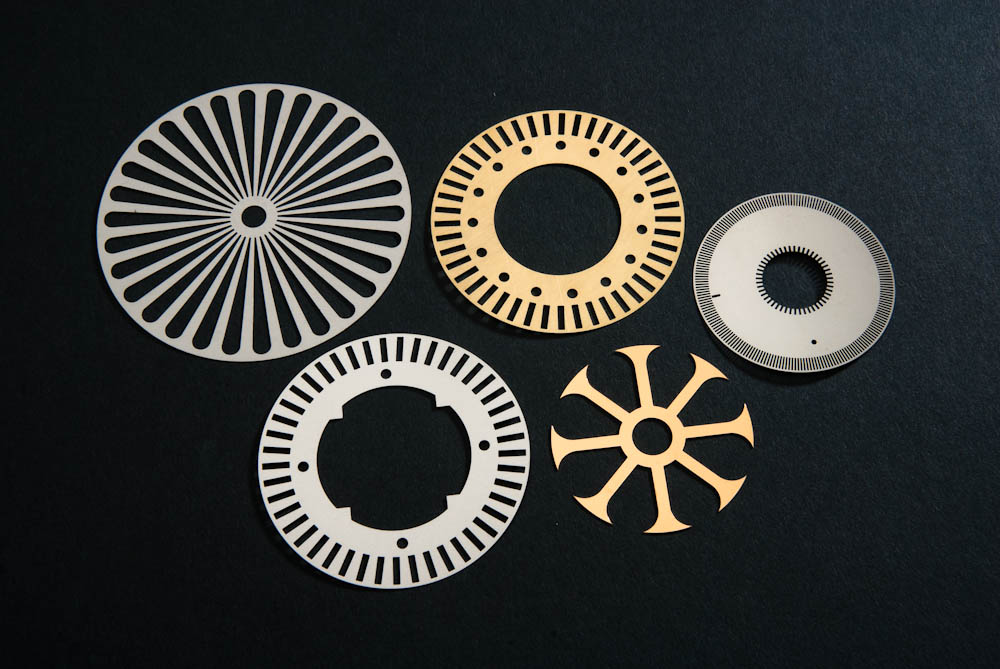

Metal Etching

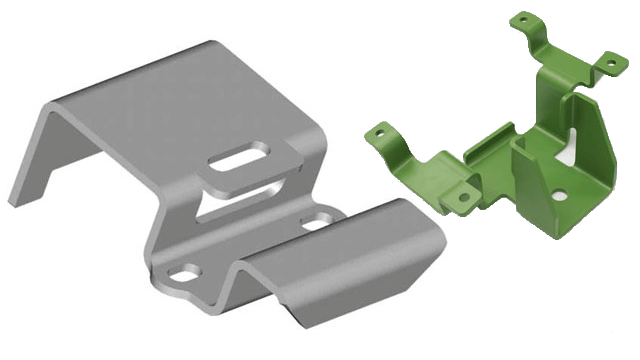

Metal Fabrication

Metal Stampings

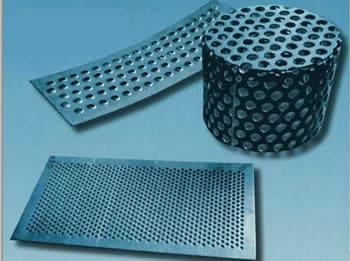

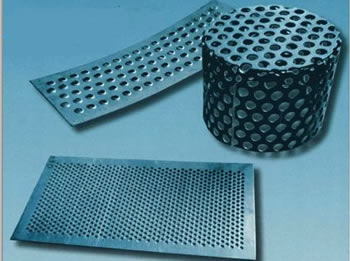

Perforated Metals

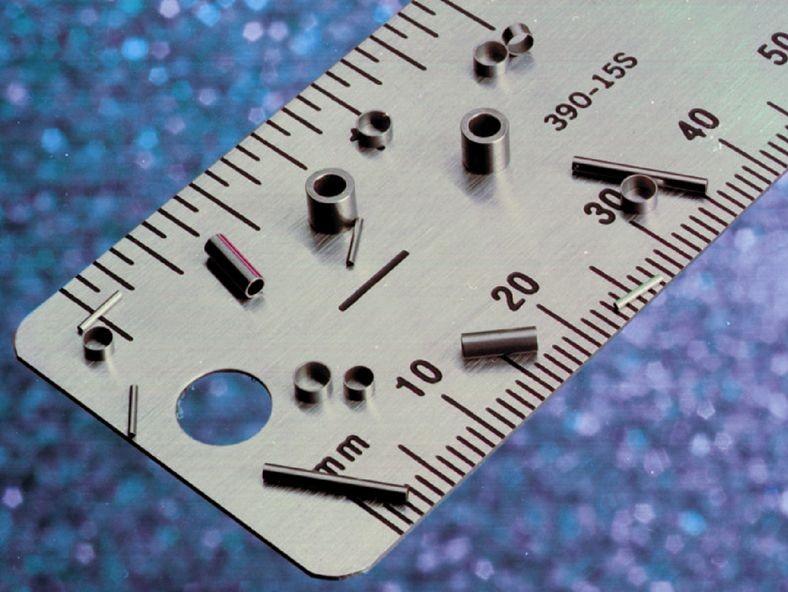

Screw Machine Products

Sheet Metal Fabrication

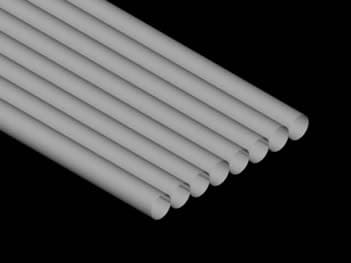

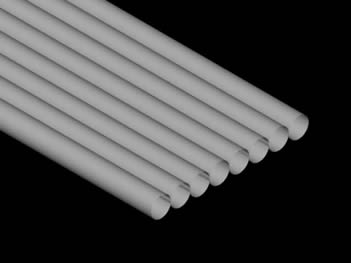

Tube Fabrication

Water Jet Cutting

Metal Cutting Services

Metal production includes operations that are designed to change the shape of metals to conform to the needs of a product. One of the essential parts of these metal forming methods is cutting, which is far more complex than simply slicing a piece of metal to a specific size.

The classification of metal cutting involves a wide array of operations with the basic purpose of removing unnecessary material from a workpiece to make it comply to design specifications. The various forms of cutting involve a variety of machines that have been engineered to perform the process efficiently and accurately.

The types of processes that perform cutting include broaching, CNC machine cutting, expanded metal process, laser cutting, stamping, etching, and perforation. These methods for metal cutting stress and shape metals to conform to the needs of an application and are designed to accomplish each operation efficiently and precisely.

Broaching is an efficient method of removing unwanted material through use of a sharp toothed broach. The two types of broaching are linear and rotary, where linear moves in a line against the surface to be changed while rotary involves a rotated broach. The types of products produced using broaching include gears, fasteners, threading, pulleys, sprockets, and bushings. There is little restriction on the types of materials that can be broached, which include plastics and copper as well as various grades of steel.

The CNC process is used to achieve a wide assortment of manufacturing functions, which includes cutting. There are several advantages to CNC programming since instructions can be directly fed into the machine, which performs cutting operations quickly and efficiently regardless of the type of cutting.

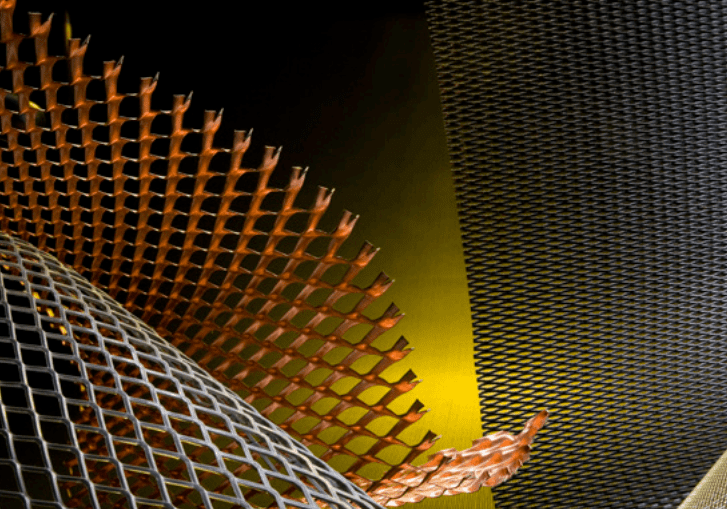

The expanded metal process is a unique and unusual method for cutting metals. Solid sheets of metal and coils are expanded to form a mesh that is cut by a knife to create a design in the mesh. The expanding process involves stretching and cutting the metal simultaneously to produce the desired design.

Laser cutting is normally included in a CNC process since cuts made by a laser are extremely precise and accurate with exacting tolerances. The term laser is an acronym for light amplification by stimulation emission radiation. The beam of the laser is a highly focused radiation wavelength. CNC programming enhances the precision of laser cuts making them nearly flawless.

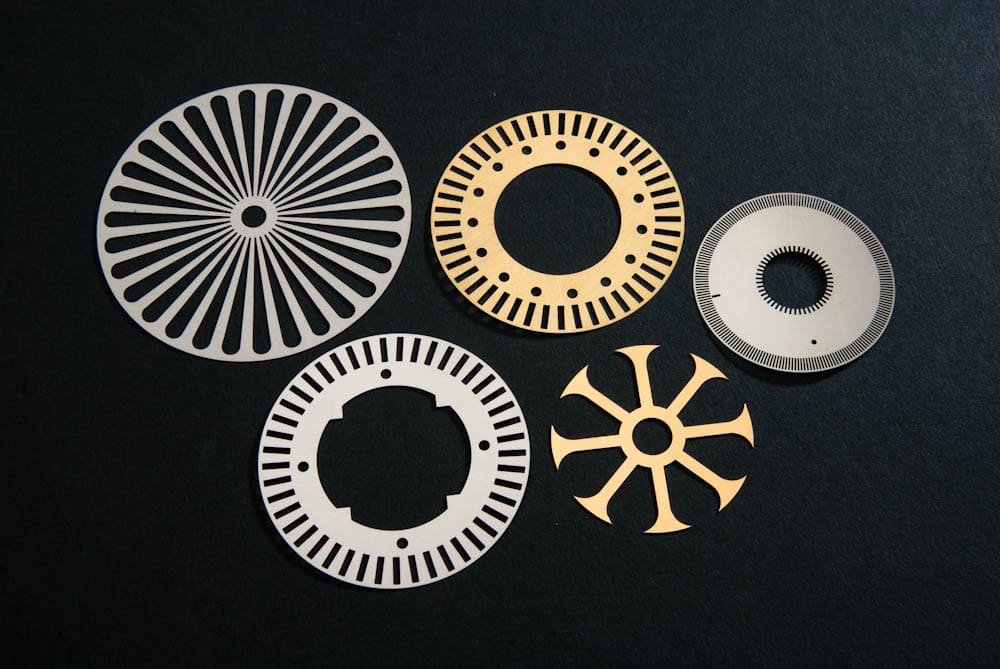

Metal etching is one of the more artistic methods of cutting since it cuts the surface of a metal to create a design, shape, or pattern by cutting grooves and fine lines. There are many varieties of metal etching, some of which include chemicals and acids as well as stamping, photofabrication, water jet cutting, and lasers, to name a few. When completed by a trained craftsman, etchings have exceptionally close tolerances as well as a smooth finish.

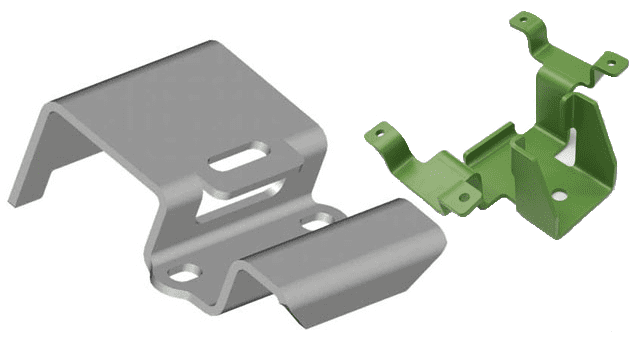

The term metal fabrication covers a wide array of processes used to shape, configure, transform, and manipulate metals. Cutting is one of the assortments of processes used by metal fabrication but plays a major role in sizing and shaping pieces to be fabricated.

Much like etching, stamping changes the surface of metals to form a design or pattern. While etching cuts into the metal, stamping uses a variety of processes to achieve its goals aside from cutting, which include bending, drawing, and blanking. Each of the different processes requires a different tool or die. A major benefit of stamping is its ability to quickly and efficiently produce finished products.

Perforating is a process that is somewhat similar to expanding but does not stretch metals to create a pattern. Metal that is perforated can serve several functions from being a decorative piece to being a protective covering for machines. The process takes metal sheet and punches it with force to create uniquely shaped holes.

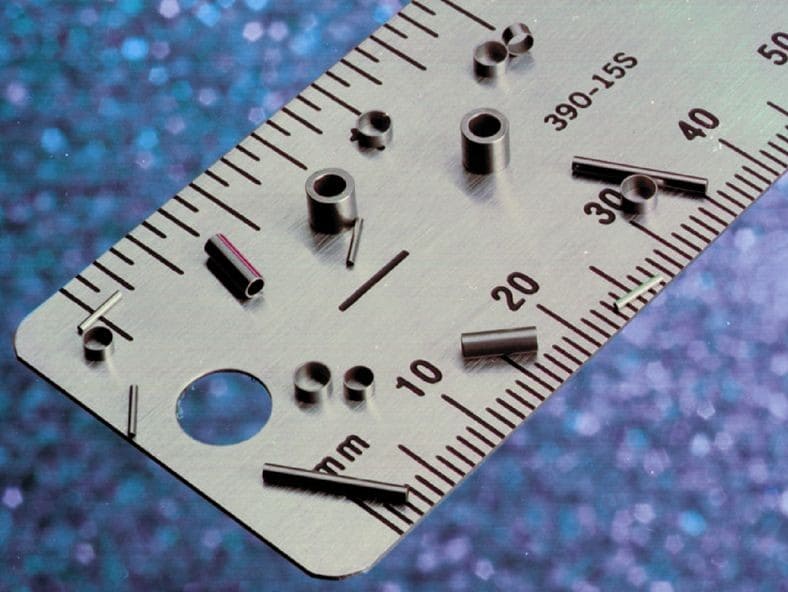

A very exciting and useful machining process is the use of a Swiss screw machine, which is a method removing excess material from a part by turning it through a cutting tool. This method of cutting is one of the most precise operations available and has become a staple for metal production.

One of the classic forms of metal fabrication is the shaping and manufacturing of tubes into a wide variety of diameters, sizes, and lengths. Tube fabrication involves bending, enlarging, and cutting tubes from a variety of metals to produce parts, components, and products.

Water jet or hydro cutting is a process of using water under high pressure to remove excess material from metals. Though water is the medium for supplying the cutting, it is enhanced with various types of abrasives that complete the cutting process. Water jet cutting is very popular for its accuracy and precision.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

Metal Stampings Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services