ProtoCAM

ProtoCAMRequest A Quote

Allentown, PAProtoCAM is a leading contract manufacturing company that specializes in providing high-quality manufacturing solutions for a wide range of industries. Founded in 1994, the company has over two decades of experience in providing customized manufacturing solutions that meet the specific needs of its clients. ProtoCAM's core competency lies in its ability to provide a comprehensive range of services, including rapid prototyping, CNC machining, injection molding, vacuum casting, and additive manufacturing. The company is equipped with state-of-the-art facilities and employs a team of highly skilled professionals who are experts in their respective fields. With this expertise and technology, ProtoCAM can deliver a diverse range of products, from small parts to large assemblies, while maintaining strict quality standards and meeting tight deadlines. ProtoCAM's rapid prototyping service allows clients to test their product designs before proceeding to full-scale production. This service involves the use of various prototyping techniques such as 3D printing, CNC machining, and vacuum casting, among others. These techniques enable clients to quickly iterate and refine their designs, reducing the time to market and overall production costs. In addition to rapid prototyping, ProtoCAM's CNC machining capabilities enable the company to manufacture high-precision parts and assemblies for a wide range of applications. The company's CNC machines can handle a range of materials, including metals, plastics, and composites, and can produce parts with intricate geometries and tight tolerances. ProtoCAM's injection molding capabilities allow the company to produce high-quality plastic parts in large quantities. The company's injection molding process involves melting plastic pellets and injecting the molten material into a mold cavity to create a solid part. This process is ideal for high-volume production runs, and the resulting parts can be used in a wide range of applications, including automotive, medical, and consumer products. The company's vacuum casting service provides a cost-effective solution for low-volume production runs. This service involves using a silicone mold to cast a small number of parts from a master model. The resulting parts are of high quality and can be used for testing, marketing, and small-scale production runs. Finally, ProtoCAM's additive manufacturing capabilities enable the company to produce complex parts and assemblies using advanced 3D printing technology. This service is ideal for producing parts with intricate geometries and for creating custom parts on-demand. In conclusion, ProtoCAM is a leading contract manufacturing company with a broad range of capabilities. Its rapid prototyping, CNC machining, injection molding, vacuum casting, and additive manufacturing services provide clients with a comprehensive manufacturing solution. With its state-of-the-art facilities and team of experts, ProtoCAM is committed to delivering high-quality products and meeting the specific needs of its clients.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

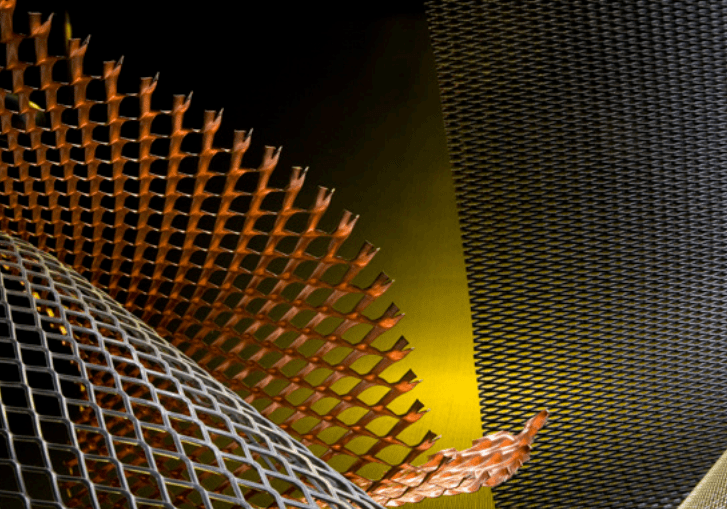

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

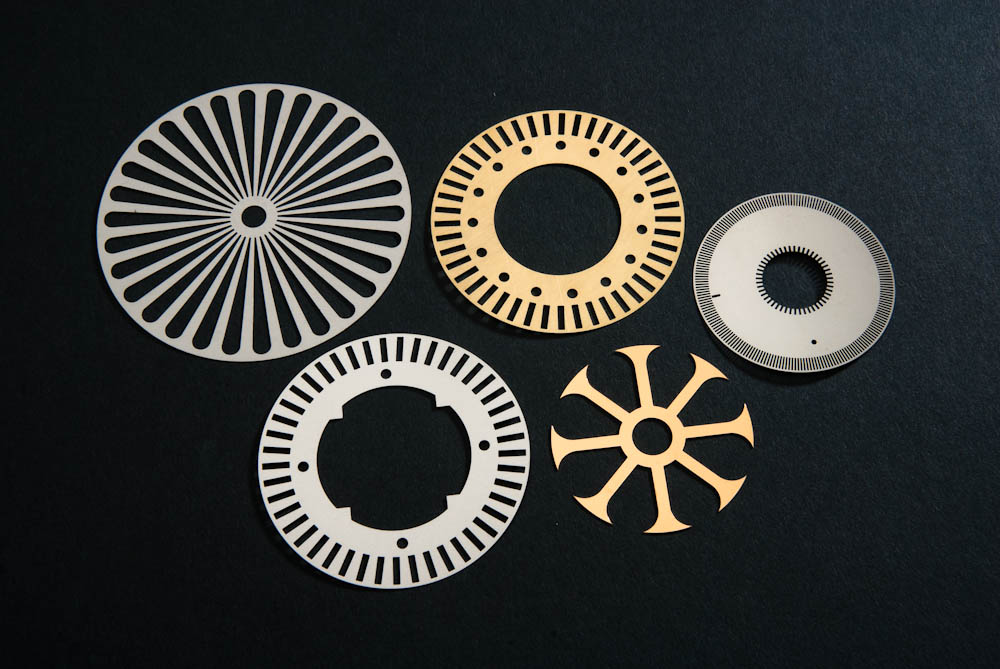

Laser Cutting Metal Etching

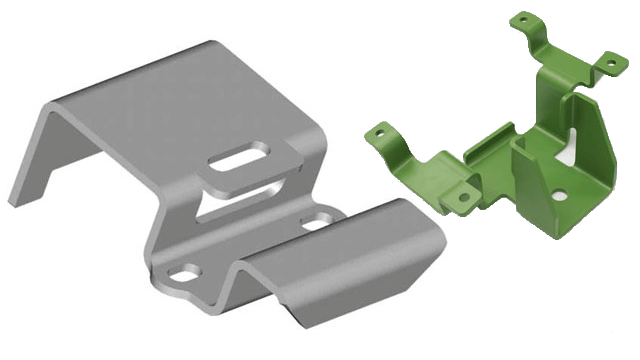

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

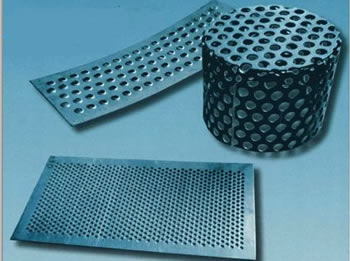

Metal Stampings Perforated Metals

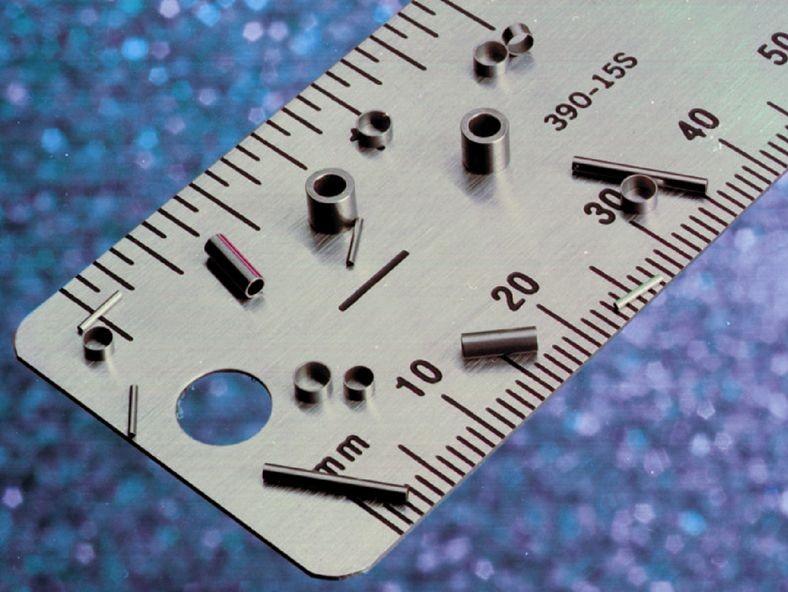

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

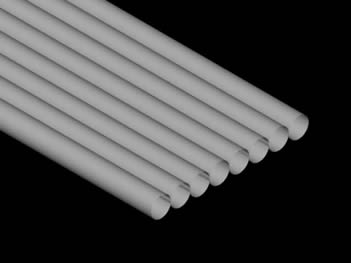

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services